| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : Yuhong

Model Number : ASTM A213 T9

Certification : ABS, BV, LR, DNV

Place of Origin : China

MOQ : 100kgs

Price : Negotiable

Payment Terms : L/C,T/T

Supply Ability : 1000 ton per month

Delivery Time : 45days

Packaging Details : Ply-wooden case with iron frame

Tube Length : Customizable

Material : Alloy Steel

Fin Spacing : Customized

Tube Connector : HFW

Fin Dia : 12.7mm

Finned Type : Studded

Pressure Resistance : High

Application : Furnace

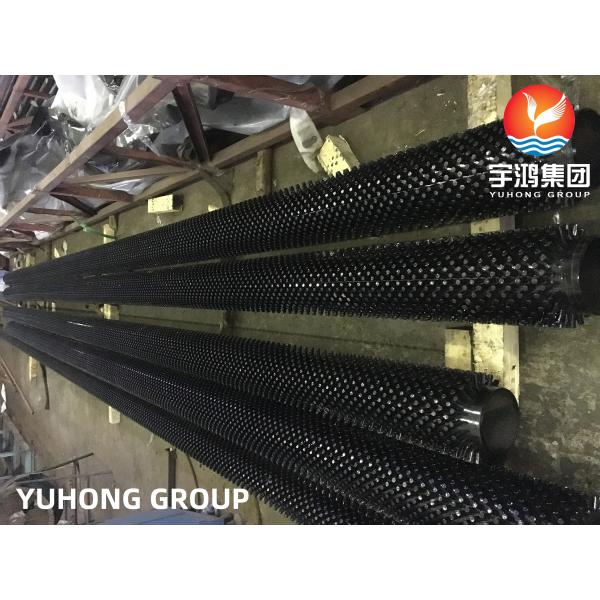

ASTM A213 T9 Alloy Steel Fin Tube, Studded Fin Tube for Furnace

ASTM A213 T9 Studded Fin Tube is a high-performance heat transfer component widely used in furnace and heater applications, particularly in convection zones. The tube body is made from T9 alloy steel, and carbon steel or alloy steel studs are resistance welded onto the tube’s surface in a uniform pattern. This design significantly enhances the heat transfer area and improves thermal efficiency in high-temperature and corrosive environments.

| Element | Content (%) |

|---|---|

| C | 0.15 max |

| Mn | 0.30–0.60 |

| P | ≤ 0.025 |

| S | ≤ 0.025 |

| Si | 0.25–1.00 |

| Cr | 8.00–10.00 |

| Mo | 0.90–1.10 |

| Fe | Balance |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 415 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 30% |

| Max Operating Temp | ~ 600–650°C |

| Hardness | ≤ 192 HB |

Material: Carbon Steel / Alloy Steel

Attachment: Resistance welding

Spacing: Typically 10–15 mm apart in helical or parallel arrangement

Maximized Heat Transfer Area

The studs increase the outer surface area significantly, improving convective heat transfer efficiency, especially in gas-to-liquid or gas-to-gas applications.

High Temperature & Pressure Resistance

T9 alloy steel is specially formulated to endure high-temperature environments, making it suitable for furnace conditions up to 650°C.

Strong Weld Bonding

Studs are welded using resistance welding, ensuring strong adhesion and long service life under thermal cycling.

Ideal for Harsh Conditions

With excellent oxidation resistance and creep strength, studded fin tubes are ideal in sooty, dusty, or corrosive environments.

Easy Maintenance

The wide stud spacing makes it easier for soot blowers or manual cleaning, ensuring consistent heat transfer performance.

| Industry | Application Area |

|---|---|

| Refineries | Convection section of fired heaters |

| Power Plants | Boiler convection tubes, HRSG systems |

| Petrochemical Plants | Radiant or convection zones in process heaters |

| Waste Heat Recovery | Flue gas heat recovery systems |

| Chemical Industry | High-temp heat exchangers in reactors |

|

|

ASTM A213 T9 Alloy Steel Studded Fin Tube for Furnace Images |